sDRY 40/80 with sDRYBIN S 15-250

The sDRY 40/80 dry air generators provide an exceptionally energy-efficient solution for material drying when paired with the sDRYBIN S drying bins. The small dryer series includes several models with drying capacities of 40 and 80 m³/h and drying bins ranging from 15 to 250 litres. All models can be configured or extended to meet growing and changing requirements. They help plastic processors cost-effectively equip individual processing machines or production cells in stages, based on demand.

The series comes as standard with dew point control and an intelligent regeneration function. Additionally, optional features such as a return air water cooler and a conveying unit are available. The conveying module allows the sDRY 40/80 to be easily integrated into existing conveying systems or equipped with a single hopper loader.

A modern control with a 7-inch touchscreen colour display allows for easy viewing and monitoring of all operating data, including historical curves. Additionally, 16 different user languages are available as standard.

- ×

sDRY 40/80 with sDRYBIN S 15-250

“Plug and Produce”

Pre-wired and ready to use.Our "Plug and Produce" products provide the ultimate hassle-free solution for a quick and seamless start-up. Designed for ease of use, each unit arrives fully assembled and ready to run—saving you valuable time and effort. With intuitive setup and an integrated power supply, you can get your production up and running immediately. Plus, all essential accessories are included, ensuring a smooth and efficient operation from day one. Experience a complete, high-performance solution that lets you focus on what truly matters—productivity and success.

sDRY 40/80 with sDRYBIN S 15-250

Compact & space-saving

Thanks to the modular, compact design, valuable floor space is saved.All dry air generators and drying bins feature a compact design and require minimal space. This enables optimal use of the production area and efficient layout of the production line.

Thanks to the integrated castors, the small dryers can be easily moved. This gives flexibility and helps with maintenance and cleaning tasks, so optimising the organisation of production.

sDRY 40/80 with sDRYBIN S 15-250

Modularity

Full flexibility for all production requirements.Thanks to the modular design concept and wide product range, all process-related requirements can be met flexibly. The sDRY series dry air generators are available in various models and can be easily combined with the sDRYBIN S drying bins. If production requirements change, so too can the drying solution.

For efficient and flexible drying, precisely tailored to the specific production needs, the dry air generators can be combined with up to 6 drying bins.

sDRY 40/80 with sDRYBIN S 15-250

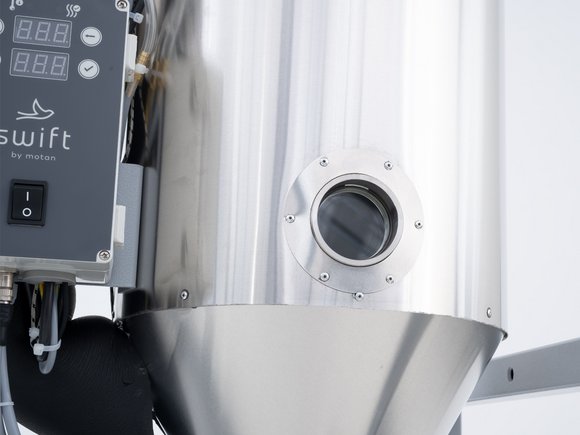

Bin design

Many extras included as standard for energy-efficient drying.The sDRYBIN S drying bins come as standard with over-drying protection, ensuring even and energy-efficient drying. Each bin features its own heating system and control to optimise material drying while saving energy. A sight glass at the front allows for easy monitoring of the material status.

By connecting to the dry air generator, the drying bin's parameters can be displayed and adjusted directly at the control display of the dry air generator. Additionally, the process trend graphics can be reviewed at the dry air generator, allowing for easy tracking of historical process data.

sDRY 40/80 with sDRYBIN S 15-250

Fully insulated drying bins

Minimal heat loss due to complete insulation.The drying bins are fully insulated on both the cylindrical and conical sections. The heat losses of the drying bins are thus reduced to a minimum.

sDRY 40/80 with sDRYBIN S 15-250

Flexible mounting options

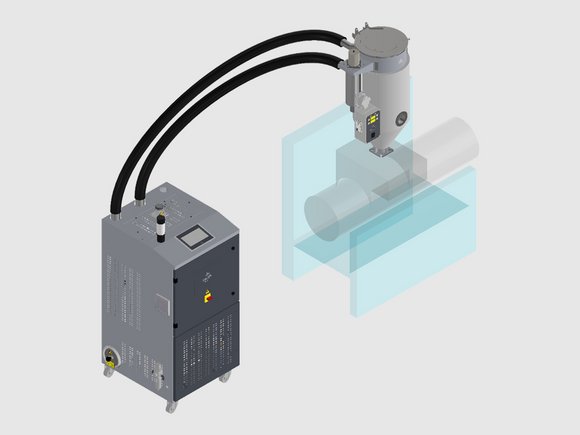

Optimal use of space for an efficient production.Two flexible mounting options are available: direct mounting on the injection moulding machine or frame installation. Both options are adaptable to space utilisation and production scenario requirements and are available in various drying bin sizes.

- The drying bin (up to 80 litres) is mounted directly on the injection moulding machine, allowing the material to transition immediately from the drying bin to the injection moulding machine. This solution is ideal for efficient space use, cost control, and preventing material re-humidification.

- The drying bin (up to 250 litres) is mounted on a support frame, the material is conveyed using a material loader with flexible hose to the injection moulding machine. This solution is suitable for complex production layouts, flexible material supply, and larger-scale conveying.

sDRY 40/80 with sDRYBIN S 15-250

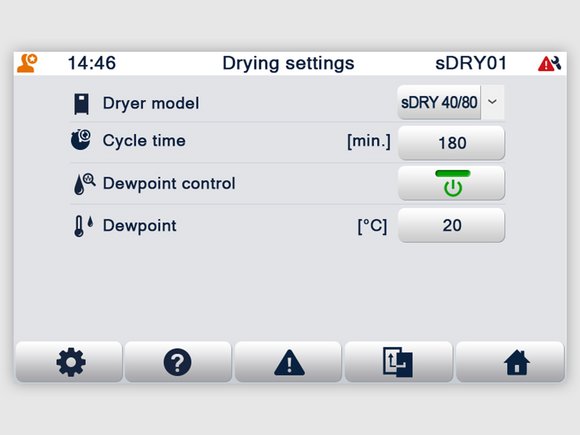

Dew point control

Stable drying with minimal energy consumption.The dry air generator comes standard with an advanced dew point control system. This ensures that the actual dew point consistently stays below the set value, effectively preventing unnecessary regeneration. As a result, the drying process is precisely controlled, maintaining consistently high performance. This not only enhances process reliability but also significantly reduces energy consumption.

sDRY 40/80 with sDRYBIN S 15-250

Intelligent regeneration

Efficient regeneration for lower energy consumption and reduced maintenance costs.Thanks to the intelligent regeneration function, moisture is completely removed from the desiccant, extending the regeneration interval and reducing energy consumption. Furthermore, the residual heat from the desiccant after regeneration is used to heat the drying bin. This allows for efficient energy utilisation, reduces energy demand, and eliminates the need for a regeneration water cooler, simplifying the system structure and reducing maintenance costs.

sDRY 40/80 with sDRYBIN S 15-250

Central touch display

Intuitive control and powerful data management.The DRY 40/80 dry air generator features an intelligent control with a Siemens PLC and a 7-inch touchscreen colour display. This user-friendly interface provides intuitive visualisation of all operating parameters and allows convenient adjustment of the drying bin settings.

In addition, the DRY 40/80 offers a powerful data management function, enabling all operating data to be tracked locally and exported via the IoT interface to SCADA, ERP and MES systems to optimise digital workflows.

sDRY 40/80 with sDRYBIN S 15-250

Conveying module option

Efficient conveying and easy maintenance.An optional conveying module is available, consisting of an IE3 blower, an air filter and a separate control cabinet. It supports closed loop conveying and effectively protects the material from reabsorbing moisture during conveying.

The unit is mounted underneath the dryer air generator to save space.

All conveying-related components can be connected directly to the control cabinet, which significantly simplifies on-site installation and facilitates regular maintenance.

The conveying module allows the connection of up to:

- 6 hopper loaders

- 5 suction boxes

sDRY 40/80 with sDRYBIN S 15-250

Return air cooler option

Air/water cooling of the return air.For greater efficiency when drying at higher temperatures or where an improved dew point is required, the dry air generator can be equipped with an air/water cooler for the return air.